Welcome to Climate Drift - the place where we dive into climate solutions and help you find your role in the race to net zero.

If you haven’t subscribed, join here:

Hi there! 👋

Skander here.

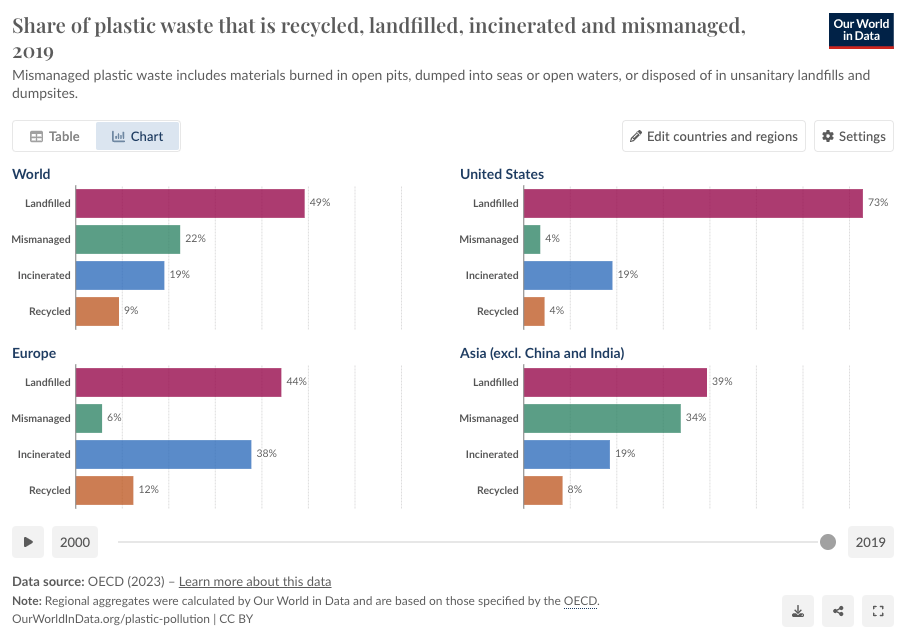

Plastic pollution is a ticking time bomb, and we're not defusing it fast enough. The numbers are staggering: less than 5% of plastics are recycled in the U.S., and even Sweden, a global recycling leader, manages only 11.8%. The rest? It ends up in our oceans, our landfills, and ultimately in our bodies. We are drowning in plastic, and the solutions we've been relying on—recycling, incineration, or wishful thinking—are simply not cutting it.

But here's the thing: we’re at a tipping point where technology, particularly AI, can turbocharge our efforts to tackle this crisis.

Hopefully AI here isn't just another buzzword; but a force multiplier that can help us rethink and redesign our entire approach to plastic waste. Whether it's optimizing reverse logistics to ensure products actually get reused, discovering new materials that can replace plastics altogether, or finally making recycling economically viable, new technologies have the potential to accelerate us toward a circular economy.

So this week Mark Lammers, a veteran in product and program management, will guide you through the challenges and solutions.

Today, we kick off with Part 1 - The Overview. Tomorrow in Part 2, we'll dive into Reverse Logistics Solutions, followed by Material Discovery in Part 3. Finally, in Part 4, we'll explore how to fix plastic recycling.

🌊 Let’s dive in

Join the Climate Drift Accelerator and turn your passion into action. We are selecting people for our next cohort now, and we're looking for talented individuals like you to make a real difference.

🚀 Apply today: Be part of the solution

But first: Who is Mark?

Mark Lammers is a seasoned product and program manager with over 25 years of experience navigating technology and business strategy. With a career spanning roles in management consulting and more than 10 years at Microsoft, Mark has shown his ability to translate complex business needs into clear technological solutions.

Mark's passion lies at the intersection of technology and sustainability, particularly in how AI can drive the circular economy. As a member of the Climate Drift Career Accelerator cohort, he is dedicated to using his expertise to address environmental challenges, focusing on how we can reduce plastic waste and design more sustainable systems.

Part One: Overview

We do a terrible job recycling plastics. In the United States we only recycle 4.5% of waste plastics. In Sweden, a recycling champion, 11.8%. Plastics are hard to recycle and are more often incinerated, landfilled, dumped into oceans, and in trace amounts they enter our bodies. Over 50% of plastic waste comes from single-use plastics used in packaging and disposable household items. There is a plastic pollution crisis that demands a shift in how we design, produce, use, and dispose of plastic.

Circular solutions— building products that are more reusable, repairable and last longer— can help. At COP28 this year, they recognized that addressing production and consumption of goods, including circular economy solutions, play an integral role in meeting the Paris Agreement numbers to halve GHG emissions by 2030. But we’re already late to the party– 2030 is 4.5 years away.

Recent advancement and availability of big data and AI models represent a threshold moment for climate work. Harnessing the power of AI can help us move faster in circular design to remove plastics from the waste system. In this paper I will give an overview of the challenges around plastic recycling and how we design for the circular economy. I will talk about three areas where AI is helping us move faster– reverse logistics, materials discovery, and fixing plastic recycling– which will be subjects for upcoming posts.

What is the Problem with Plastic Recycling?

Plastics are synthetic or semi-synthetic materials that use polymers as a main ingredient. Their advantage in product design– plasticity, adaptability, weight, durability, flexibility, and cost– has led to their widespread use. But they take a very long time to break down.

In 70 years, there has been 8.3 billion metric tons of plastic produced, with around 6.3 billion metric tons of that becoming waste. And only 9% of that waste has been recycled. Every molecule of plastic produced since 1907 is still present in the environment.

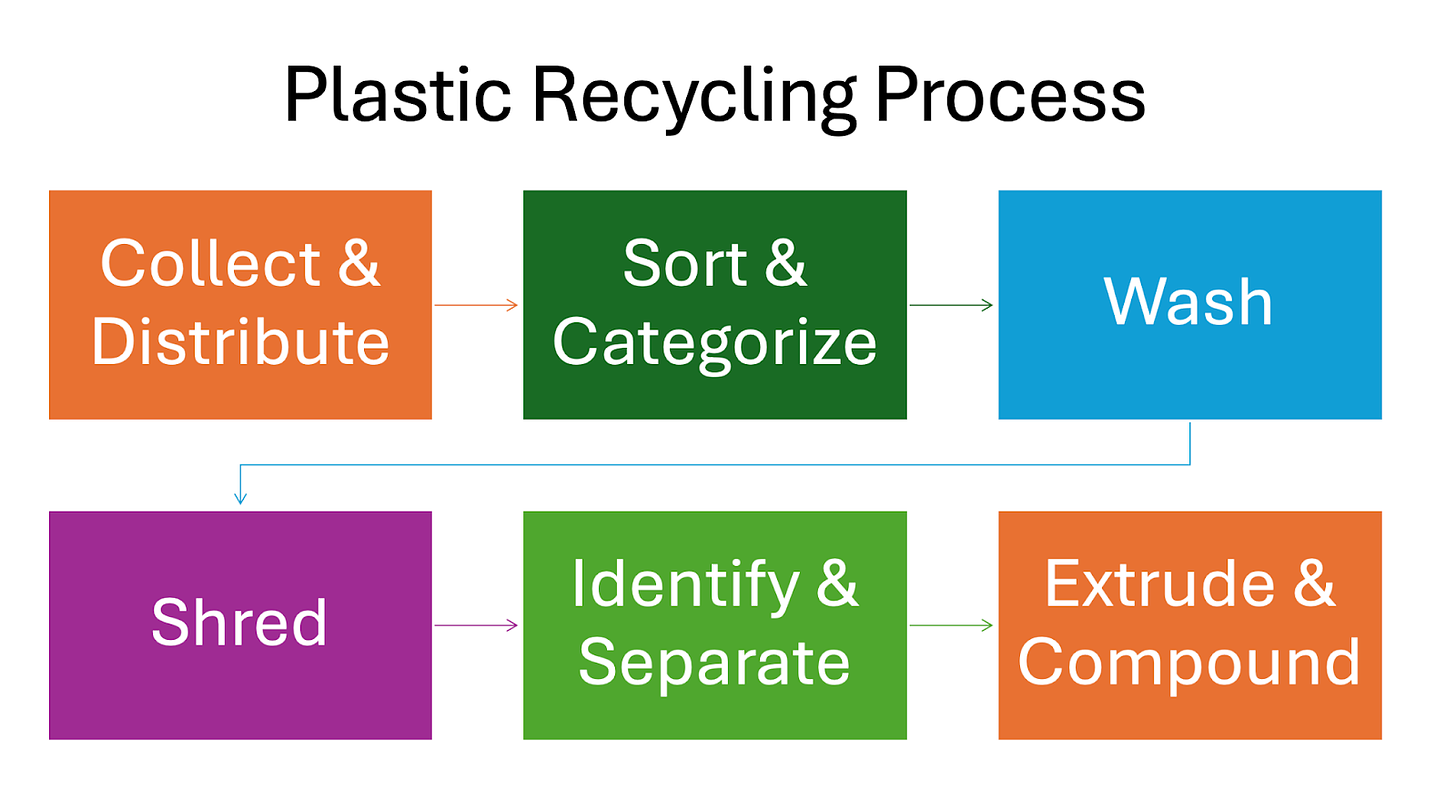

The process of recycling plastic:

Collect from homes, business and public recycling bins and distribute to recycling centers.

Sort and categorize into the seven different types of plastic based on their resin code.

Wash to remove impurities that can ruin the recycling process.

Shred plastic into smaller pieces.

Identify plastic for class and quality and separate them based on density.

Extrude and compound into pellets that can be used in the fabrication of post recycle products.

Recycling plastic has challenges:

Insufficient plastic is collected. People, unsure what is happening to their plastic recycling, don’t recycle enough.

Contamination. Paper labels and food waste lowers the quality and makes it difficult to recycle.

Sorting. There are thousands of different types of plastic, each with unique properties that affect their structure, color and melting point. As these materials cannot be processed together, collection, sorting and treatment are much more complicated and expensive.

Profitability. In the US, for example, recycling is a for profit industry. If no one will buy your recycling, you’ll need to put it in a landfill or burn it.

Designing for the Circular Economy

Designing products for the circular economy involves a radical, restorative and regenerative approach. Previous linear models involved extraction of virgin material, manufacturing, use and disposal into the waste stream. Designing for circularity involves fundamentally rethinking how our products are manufactured, used, and returned into a circular system. It means designing products that are easy to return, repair, refurbish and reuse. Designing products that last longer and are made out of more sustainable materials. And creating new flows for reuse of materials.

Removing of plastics from the waste system in a circular way means:

Figuring out the reverse logistics flow making it possible for retrieval of the products.

Discovering new and useful materials as an alternative to using single use plastics.

Fixing the plastic recycling model so that plastics can easily be turned into material that can be used in new products.

How Can AI Help Us?

AI has exploded in the past few years and I believe that large data models can help propel us beyond human innovation in climate initiatives, the circular economy included. When I started this research project I wondered if there was a single use case for AI in circular design. I soon realized that there were many use cases in designing for a circular economy.

AI is a superset of big data that includes machine learning, deep learning and generative AI.

According to the Ellen MacArthur Foundation, a leader in circular design research, “AI helps to solve problems through performing tasks which involve skills such as pattern recognition, prediction, optimisation, and recommendation generation, based on data from videos, images, audio, numerics, text and more.”

In my research on AI applications I found three areas particularly promising:

Reverse logistics– AI can help with product data tracking and enhancing the flow of product return and reuse.

Materials discovery– Big data models can help with identifying and creating plastic alternatives and putting that power into the hands of designers.

Fixing plastic recycling– AI powered robots can help sort plastics better and big data models have led to the discovery of plastic eating enzymes.

I believe that AI can help us accelerate the removal of plastic from the waste system. The use cases are practical and innovative. I see the power of AI to accelerate us in circular design and removal of plastics from waste.

In my next post: How Kadeya, a start-up hydration company, is closing the gap on product data that enables a closed loop system for easy returns. And how Optoro, a reverse logistics company is helping companies like IKEA to enable a frictionless return system.

I am passionate about the circular economy and removing plastics from waste. Please reach out to me on LinkedIn if you’d like to discuss these topics more.

This is a remarkably compact and accessible introduction to AI vs. The Plastics Problem.

On to Part 2!

I want you to learn more…what CA companies are doing thus? Are these all private or are governmental agencies involved. How can I get involved? Mark, your writing is exceptional. The subject, so important.