Welcome to Climate Drift - the place where we dive into climate solutions and help you find your role in the race to net zero.

If you haven’t subscribed, join here:

Hi there! 👋

Skander here.

Today, in Part 4 of our Plastics & AI series, we’re diving into one of the most debated topics in the circular economy: plastic recycling.

In Part 1, we explored the scale of the plastic waste crisis and AI's potential to revolutionize our response. In Part 2, Mark focused on reverse logistics, streamlining the return, repair, and reuse of products. Part 3 looked into materials discovery, a true frontier technology.

Recycling has long been touted as the solution to our plastic problem, but is it really the broken promise of the linear economy? Perhaps. But I believe there’s still room to fix it, especially by leveraging new technologies to pull plastics out of the waste system before they get there.

We’ll look at how AI is helping to speed up processes like sorting and how enzymes can break down plastics more efficiently, revolutionizing how we recycle.

And while recycling won’t be the magic bullet for our plastic problem just yet, these innovations are showing real promise.

🌊 Let’s dive in.

Join the Climate Drift Accelerator and turn your passion into action. We are selecting people for our next cohort now, and we're looking for talented individuals like you to make a real difference.

🚀 Apply today: Be part of the solution

But first: Who is Mark?

Mark Lammers is a seasoned product and program manager with over 25 years of experience navigating technology and business strategy. With a career spanning roles in management consulting and more than 10 years at Microsoft, Mark has shown his ability to translate complex business needs into clear technological solutions.

Mark's passion lies at the intersection of technology and sustainability, particularly in how AI can drive the circular economy. As a member of the Climate Drift Career Accelerator cohort, he is dedicated to using his expertise to address environmental challenges, focusing on how we can reduce plastic waste and design more sustainable systems.

Part Four: Fix Plastic Recycling

Circularity means creating products that last longer and are easier to reuse. Is recycling a broken promise, a vestige of the linear economy that placates people into thinking that they are doing the right thing for the environment? Possibly. But I believe it is still worth trying to fix plastic recycling in order to pull plastic out of the waste system before it gets there.

In previous posts I wrote about the problem with plastic recycling. I talked about how AI is helping us accelerate circular design to remove plastics from the waste system. I dove deep into AI use cases in reverse logistics and materials discovery. In this post I am going to jump into two areas where AI is revolutionizing plastic recycling: The creation of plastic eating enzymes that accelerate the breakdown of plastic and AI-powered sorting robots which improve sorting issues.

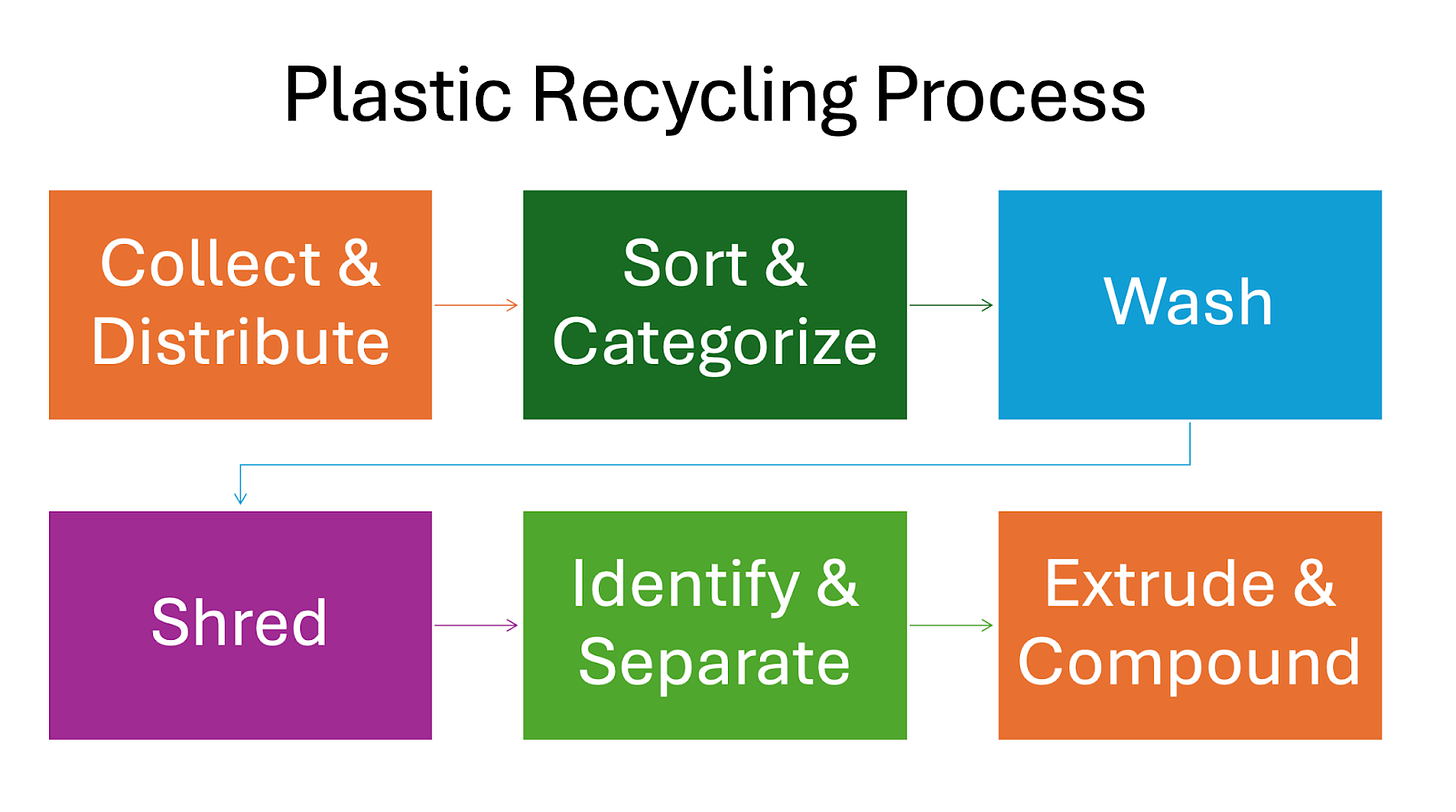

The process for recycling plastics involves:

Collect from homes, business and public recycling bins and distribute to recycling centers.

Sort & categorize into the seven different types of plastic based on their resin code.

Wash to remove impurities that can ruin the recycling process.

Shred plastic into smaller pieces.

Identify plastic for class and quality and separate them based on density.

Extrude and compound into pellets that can be used in the fabrication of post recycle products.

Challenges with plastic recycling:

Insufficient plastic is collected – people, unsure what is happening to their plastic recycling, don’t recycle enough.

Contamination – paper labels and food waste lowers the quality and makes it difficult to recycle.

Sorting -- there are thousands of different types of plastic, each with unique properties that affect their structure, color and melting point. As these materials cannot be processed together, collection, sorting and treatment are much more complicated and expensive.

Profitability – in the US specifically, recycling is a for profit industry. If no one will buy your recycling, you must put it in a landfill or burn it.

University of Texas – Plastic Eating Enzymes

In 2022, engineers and scientists at the University of Texas successfully produced an enzyme, PET Hydrolase, that can rapidly break down plastics (depolymerization) and then chemically put them back together (repolymerization) so they are ready for reuse. “Through these more sustainable enzyme approaches, we can begin to envision a true circular plastics economy,” says Hal Alper, professor in the McKetta Department of Chemical Engineering at UT Austin.

The project focused on polyethylene terephthalate (PET), a significant polymer that makes up the most recyclable of plastics. Much of our single-use plastics -- consumer packaging, soda and water bottles, fruit and salad packaging– is PET. These enzymes could address 12% of all global waste.

Application of PET Hydrolase had been blocked by their lack of robustness to pH and temperature ranges. But the research team was able to use a structure-based, machine learning algorithm to engineer a robust and active PET hydrolase that can achieve depolymerization and repolymerization in 24-48 hours. My research did not uncover any current commercial use of PET hydrolases yet, but research is progressing towards potential commercial applications.

Glacier – AI-powered Sorting Robotics

Sorting is one problematic area for recycling. Glacier, a San Francisco based company has developed an AI-driven sorting robot that can identify over 30 categories of recyclable materials in real time. It can recognize broad categories like PET, the most recyclable of all the plastics. The company claims that one Glacier robot can prevent over 10 million items per year from ending up in landfills. They aim to provide high ROI for recycling facilities, balancing cost and performance. The company recently raised $7.7M in funding from Amazon’s Climate Pledge fund and is partnering with mega-retailer Amazon to pilot a project focusing on sorting novel material that can be easily recycled.

Glacier is not alone: ZenRobotics and CleanRobotics are examples of other AI-driven robotic sorting solutions that are moving forward in that space.

Improving sorting using robotics and accelerating recycling via enzymes will not fix plastic recycling. Plastic recycling will still be problematic for some time because of lack of volume recycled and lack of profitability. However, these two use cases represent improvements in the recycling space where we could move the needle. I am bullish on the use of sorting robots for plastic recycling. The sooner we can get them deployed to municipal waste facilities the better. But will it fix the plastic recycling mess? It’s still too early to tell.

I am passionate about the circular economy and removing plastics from waste. Please reach out to me on LinkedIn if you’d like to discuss these topics more.