Welcome to Climate Drift - the place where we dive into climate solutions and help you find your role in the race to net zero.

If you haven’t subscribed, join here:

Hi there! 👋

Skander here.

In Part 1, we examined the staggering scale of the plastic waste crisis and how AI has the potential to revolutionize our approach to tackling it. In Part 2, we shifted our focus to the critical role of reverse logistics—how we can streamline the return, repair, and reuse of products, transforming the way we manage the end of a product’s lifecycle.

Today, in Part 3, Mark’ll explore one of the frontier areas of climate innovation: materials discovery.

Removing plastics from the waste stream entirely is one of the most effective ways to reduce pollution. But with so many plastic alternatives either too expensive, not durable enough, or hard to find, how can we design better materials?

🌊 Let’s dive in.

Join the Climate Drift Accelerator and turn your passion into action. We are selecting people for our next cohort now, and we're looking for talented individuals like you to make a real difference.

🚀 Apply today: Be part of the solution

But first: Who is Mark?

Mark Lammers is a seasoned product and program manager with over 25 years of experience navigating technology and business strategy. With a career spanning roles in management consulting and more than 10 years at Microsoft, Mark has shown his ability to translate complex business needs into clear technological solutions.

Mark's passion lies at the intersection of technology and sustainability, particularly in how AI can drive the circular economy. As a member of the Climate Drift Career Accelerator cohort, he is dedicated to using his expertise to address environmental challenges, focusing on how we can reduce plastic waste and design more sustainable systems.

Part Three – Materials Discovery Solutions

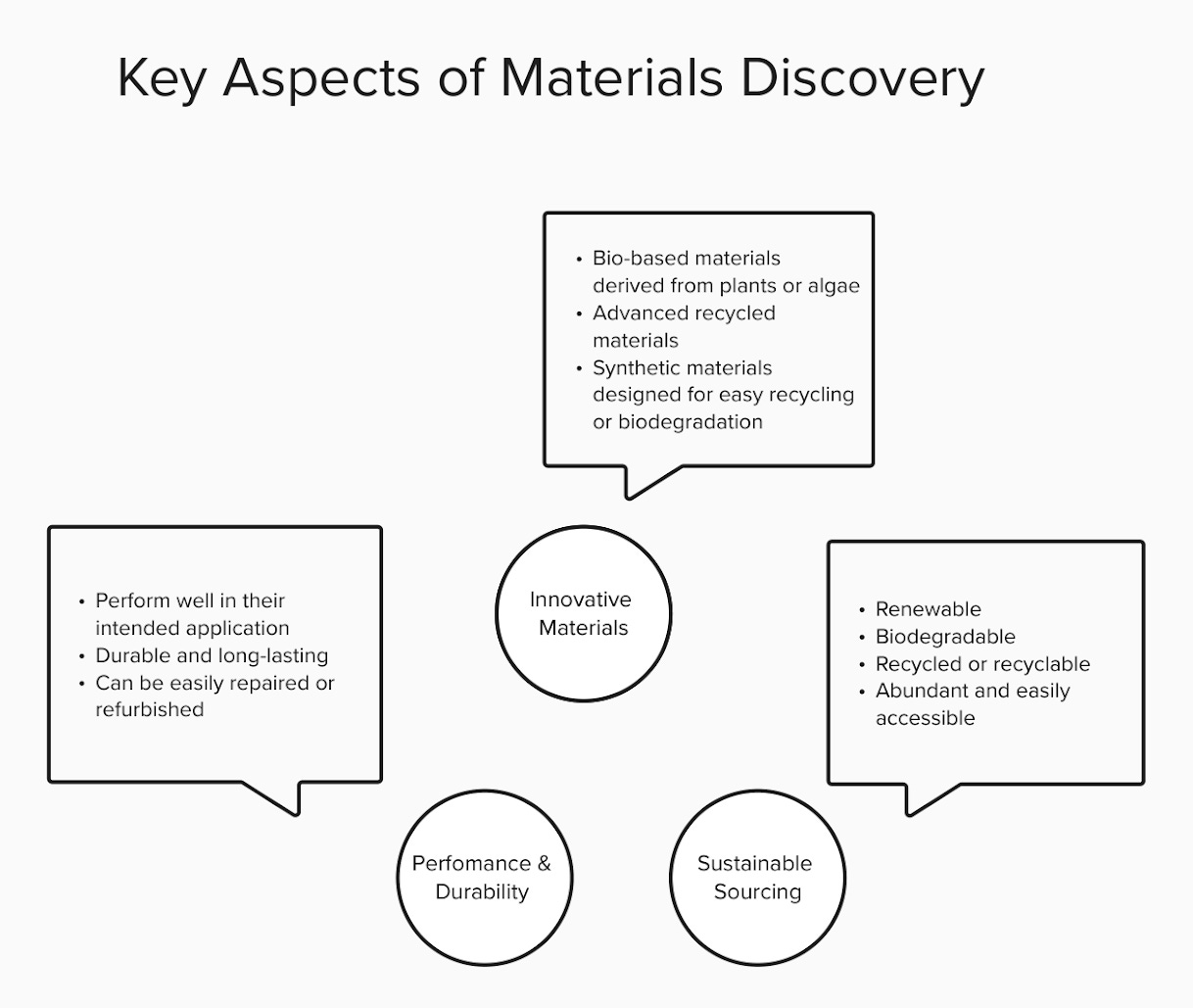

Designing plastics out of product design is the probably most effective way of removing it from the waste stream. Plastic alternatives abound, but are not always easily discoverable, are not as durable, or are sometimes more expensive. In earlier posts I explained the problems around plastic recycling and how AI can help us move towards a circular economy where plastics are removed from the waste system. I dove deeper into use cases for AI to help accelerate figuring out reverse logistics. In this post I will dive deep into two areas where AI can help accelerate circular design in materials discovery, sustainable polymers and putting the power of AI-driven materials discovery in the hands of designers.

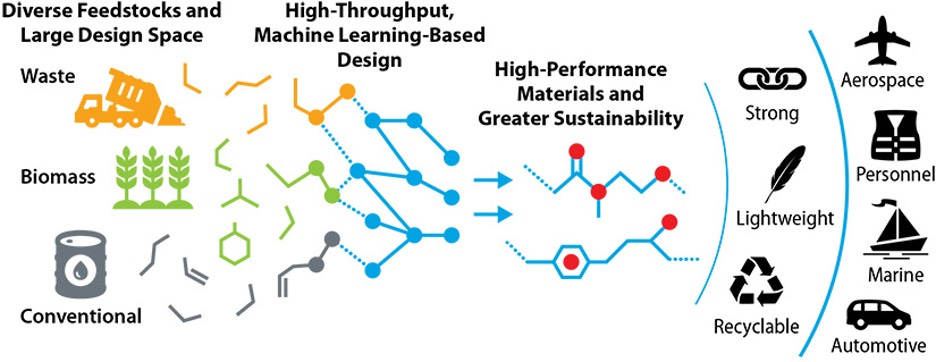

NREL - Sustainable Polymers

Scientists and engineers at the National Renewable Energy Laboratory (NREL) have developed a machine-learning tool called PolyID to help users find more sustainable polymers for various applications. Polymers are made more sustainable by nitrogen-rich biomass and waste to the ingredient list, things like corn stalks, algae and even garbage.

According to Brandon Knott, an NREL scientist, the algorithm behind PolyID is “a state-of-the-art advancement to a foundational approach known as ‘group-contribution theory’. The tool builds associations between arrangements of oxygen, hydrogen, carbon, and other elements and material properties to predict attributes like elasticity, heat tolerance, and sealant performance.”

NREL scientists have used PolyID to screen 15,000 plant-based polymers in search of more biodegradable alternatives to food packaging films. The team prioritized biodegradability and lower greenhouse gas footprint properties in PolyID to come up with a list of 7 polymer designs that could be made from biomass. NREL is publicly available online.

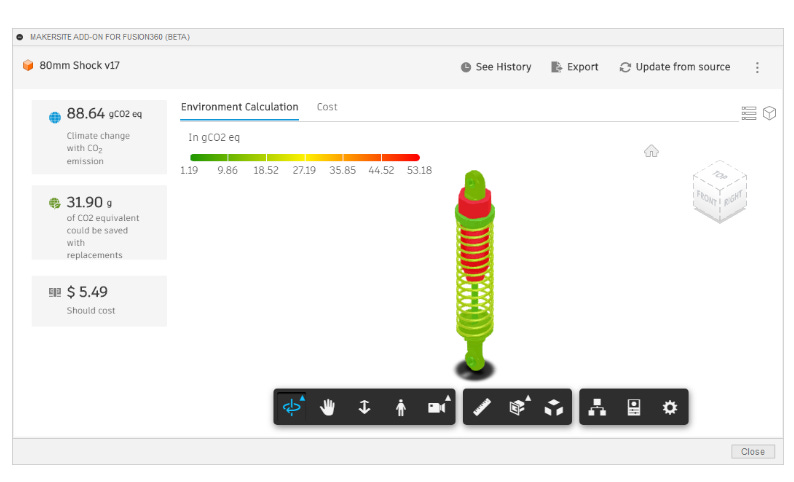

AutoDesk and Makersite– Give Designers the Power of AI

What if you gave designers the ability to understand the environmental impact of their designs using an AI engine? Autodesk, Swiss creator of computer aided design (CAD) systems, and Makersite, a German AI company, have partnered on Autodesks’s Fusion product that gives designers the ability to see the climate impacts of their products. Despite the public wanting more sustainable products, today less than 1% of products have sustainability as a design requirement. But with Makersite’s AI solution, Autodesk Fusion users can access over 300 materials, cost, and sustainability insights. Makersite has the environmental impact and cost data. Autodesk Fusion has slick interactive product design capability. This integration allows designers to assess the sustainability of their designs directly within the Fusion environment. Designers can request Makersite to calculate climate change impacts of their design as well as cost estimates of the bill of materials (BOM). The tool makes suggestions on how to reduce these impacts in the form of material alternatives. Results can be visualized in a grid or as heatmaps.

“The stats tell us that 80% of the ecological impacts of a product are locked down in the design phase. Therefore, the design phase of a product is the first and most necessary stage to get more sustainable goods into the world successfully,” says Neil D’Souza, founder of Makersite. “However, eco-design is only feasible when designers have data about the sustainability of their product and its compliance, costing, environmental, health, and safety criteria. By integrating our data, AI, and calculation engines into Fusion, product designers are provided with clear and actionable insights so they can decide how to make their designs more sustainable.”

Removing plastics from waste involves using alternative materials. Putting the AI power of climate impact into the hands of designers, as opposed to product strategists, Fusion and NREL have empowered designers to build products with safer and more circular materials. Designing products that use alternative, sustainable, and reusable materials is the ideal situation and AI can help engineers and designers make those materials choices. The Autodesk/Makersite partnership is a powerful one as Autodesk has a large market share among CAD users. The NREL database is powerful because it is publicly funded and widely available. Materials innovation has been a puzzle for the circular economy, but I am confident that we can accelerate using data.

In my next post: How the creation of a plastic eating enzyme at the University of Texas and use of AI-driven sorting robots built by Glacier could help fix plastic recycling.

I am passionate about the circular economy and removing plastics from waste. Please reach out to me on LinkedIn if you’d like to discuss these topics more.